The manufacture of high precision mechanical parts is one of our core competencies. We can carry out any milling and lathe work using CNC machines.

Ltd Videoelektronica performs a full cycle of machine parts designing, which includes:

- Development of technological process and control programs;

- Production of a finished product with all the necessary processing steps.

Our company has a modern fleet of high-tech equipment, which ensures the implementation of various types of metalworking, as well as the entire range of mechanical assembly and auxiliary work, including welding, heat treatment and electroplating.

The qualifications of our employees and the capabilities of the equipment allow us to produce various mechanical parts of high precision and varying complexity at the highest possible quality level.

Lathes park

- HaasST-25 1 pc, CNC — equipped lathe complex;

- HaasST-10 1 pc, CNC — equipped lathe complex;

- BD-10 Sinumeric 2 pcs, CNC-equipped manufacturing lathe.

Lathe work includes many types of technological operations: processing of end, conical, cylindrical shaped surfaces and ledges; cutting off a part of the workpiece; turning a groove; machining a hole on a workpiece by boring; drilling; countersinking; reaming; rolling; threading.

We carry out lathe work according to the client’s drawing or product sample.

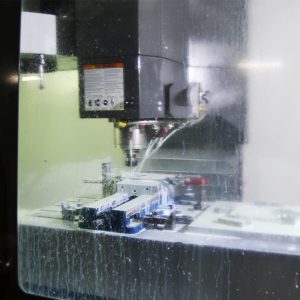

Park of milling machines

- Haas VF-3 TR-210 1 pc, 3 + 2 Axis CNC-equipped milling machining center, max workpiece size 210 * 210 * 125 mm;

- Haas VF-5 1 pc, 3-axis CNC-equipped milling machining center, max workpiece size 1200 * 650 * 640 mm;

- Haas VF-4 Super 2 pcs, 3-axis CNC-equipped milling machining center, max workpiece size 1200 * 500 * 640 mm;

- Haas VF-3 1 pc, 3-axis CNC-equipped milling machining center, max workpiece size 1000 * 500 * 640 mm;

- Haas VM-3 Moldmaker 1 pc, 3-axis CNC-equipped milling machining center, max workpiece size 1000 * 600 * 640 mm;

- Haas VF-2 1 pc, 3-axis CNC-equipped milling machine, max workpiece size 750 * 400 * 500 mm;

- Haas VF-1 1 pc, 3-axis CNC-equipped milling machine, max workpiece size 500 * 400 * 500 mm;

- HaasMiniMill 1 pc, 3-axis CNC-equipped milling machine, max workpiece size 400 * 300 * 250 mm.

The work is carried out on CNC milling machining centers. Thanks to the centers both vertical and horizontal milling is possible, as well as milling at different angles using various tools: rotary tables and dividing heads.

All products undergo strict quality control at every stage of the milling work. Technical control of metal milling allows us to guarantee the high quality of each specific metal product.

Milling is often the next step after lathe work when working with workpieces.

Milling works are carried out according to customer’s drawings or samples of devices parts.